Reasons for concrete crack and methods to avoid it

Reasons for concrete crack and methods to avoid it

TMT Bars

| 10 August 2022

10 August 2022

Whether you are a millionaire or working on a limited budget, one crucial thing in constructing residential buildings or your own house is the construction cost. According to the experts, you can effectively keep the construction price down in your favor if you follow some common tricks and strategies.Concrete is a long-lasting, strong and resistant to cracks. However, there are instances where the concreate may develop cracks. This may happen for a number of reasons. Following are some of the common causes of concreate cracks

Causes of Concrete Cracks:

- Due to temperature variations, concrete expands and contracts.

- Concrete surfaces shrink as a result of water loss.

- Inadequate shaking when placing the concrete.

- The improper cover used during concreting; excessive use of water and cement to make the concrete workable.

- Due to reinforcing steel corroding.

Method to Fix Concrete Cracks:

1. Reduce the Amount of Water in Concrete:A low water-cement ratio will impact the quality of concrete. Concrete has higher strength and fewer cracks when the W/C ratio is lower. The proportion must not exceed 0.5, as higher values affect workability. Less water means less shrinkage and fewer fractures due to water loss during hardening.

2. Using a Proper Concrete Mix and High-Quality Materials:Concrete must be mixed and proportioned correctly. Too little cement or too much water weakens the concrete. Use high-quality, dense aggregates with optimal gradation to reduce shrinkage. Avoid admixtures that promote shrinkage.

3. Surface Finishing for Concrete:Use appropriate finishing techniques and timing. Flat troweling and floating are recommended. Avoid overworking the concrete and vibrating excessively, which can cause bleeding. Finishing while there is surface water can reintroduce water and lead to cracking.

4. Proper Concrete Curing:Curing prevents rapid moisture loss. After hardening, maintain wetness using mortar borders, wet cotton mats, or curing compounds. Avoid applying pressure during curing, which should ideally last up to 28 days.

5. Concrete Should Be Placed and Vibrated Correctly:Proper placement and vibration reduce trapped air and ensure even distribution, which minimizes cracks.

6. Concrete Control Joints Provision:Install control joints at regular intervals (typically every 8–12 feet for 4-inch slabs) to manage shrinkage cracking. These pre-determined joints guide cracks along desired paths rather than random locations.

Conclusion:Understanding the root cause, type, and pattern of concrete cracks is essential. Use the best-quality materials and follow scientific processes. For added durability and strength, consider using SRMB TMT Bars along with premium-grade cement and aggregates to build long-lasting concrete structures.

Popular Blogs

TMT Bars

Buy TMT Steel Online: Why SRMB Is the Trusted Choice

19 Jul 25

19 Jul 25

TMT Bars

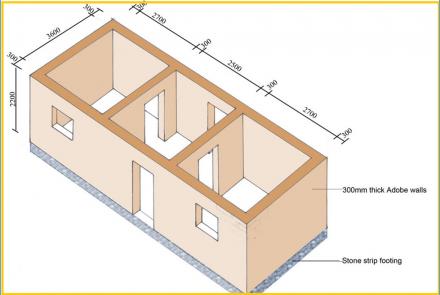

All that You Need to Know About Load Bearing Masonry and Frame Structural Walls

30 Aug 22

30 Aug 22

TMT Bars

5 Tips to Save Construction Costs in 2022

10 Aug 22

10 Aug 22

TMT Bars

Reasons for concrete crack and methods to avoid it

10 Aug 22

10 Aug 22

TMT Bars

TMT Price in West Bengal: FAQ and Answers

24 Jun 22

24 Jun 22

TMT Bars

5 Tips to 'Go Green' on Your Next Construction Project

18 Jun 22

18 Jun 22